23 Aerosol Propellant Losses Will Cost You Money and Ruin Your Plant

09/06/2020Did you know that aerosol propellants can be lost in 23 places?

It is not only the propellant gas and money that are lost, but also the possibility of destroying the plant.

Since there is almost no way to monitor and measure the use of propellants, it is very easy to lose them (the most commonly used is liquid petroleum gas: propane/butane).

Furthermore, most companies lose propellants in several places, never in just one.

All companies lose propellants, but some companies lose much less than others.

This list of the 23 most common areas of lost propellants is by no means representative of all possible areas of loss, and some unimportant areas have been omitted.

Before discussing the 23-item long list, let me introduce you the 5 items that I feel are most important.

1. Poorly Designed Gas Filling Head

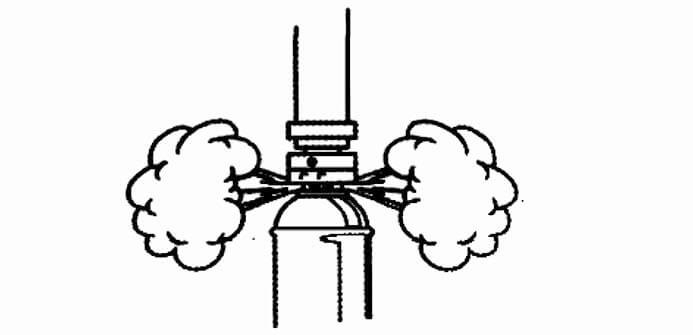

When filling the aerosol, leaks are inevitable at the filling head. The filling head has an inner valve and a seal, and the aerosol valve also forms a seal.

All the material between the seal of the filling head and the seal of the aerosol valve is lost and this leakage inevitably always occurs.

2. Poor Maintenance of the Gas Filling Head

Good-quality gas filling heads are able to operate for a long time, but they still require maintenance. Filling heads without guaranteed quality require maintenance after a short period of operation and the quality of their spare parts may also be questionable.

In any case, a maintenance shutdown is necessary as soon as a visible leak is detected in the filling head. Icing indicates a serious leak. There should never be ice on the filling head. Any ice found anywhere should be shut down for service immediately.

3. Use the Wrong Gas Filling Head

Thousands of tonnes of LPG are lost every year due to the wrong filling heads used by aerosol filling companies. A typical example is the filling of Precision valves with Coster fillimg heads.

Another example is the filling of a Precision valve with a nozzle using a filling head that does not have “fill with nozzle”. In this case, at least to the naked eye, a large cloud of propellant gas vapour is visible as the filler leaves the can.

Every machine operator makes this mistake from time to time, but a good machinist will detect their mistake, stop the machine and replace the filling head with a suitable one.

4. Inferior Quality, Counterfeit Aerosol Filling Equipment

Aerosol filling equipment is difficult to fully and successfully replicate; components can be measured but tolerances are difficult to determine; material specifications are unknown; cylinder surface finish cannot be measured and controlled.

Imitation machines are sold at a low price, so only inexpensive raw material substrates can be used; imitations can be operational, but always leak more propellants than quality machines.

Leak-related problems are the price of inferior machines, but hose rupture is a serious safety issue – and it’s always associated with inferior, inexpensive machines.

A ruptured hose can lead to a serious accident that can destroy a filling plant. Therefore, it is necessary to use high quality hoses and couplings.

5. Pump and Pipe Leaks

Most companies test for leaks in pumps, piping and connections early in the construction process. Once the plants are set up and running, they are no longer inspected and small leaks become persistent.

Thousands of tons of propellant gases are lost because companies don’t have leak detectors or don’t use them to check their machines and entire facilities on a weekly basis.

These are the main aspects of the leak, but the leak is far from limited to these five locations.

So here below is a brief discussion of the 23 leaks.

During delivery and transport process.

1. Wealthy Weigher

There are many tricks here for the weigher to collect extra money and give customers the illusion that they are getting more LPG when in fact less is actually being sent out than what is shown on the scale.

2. Driver’s Threshold

It is not uncommon in many countries for drivers to tamper with their goods before and after delivery, with or without the help of a weighmaster. The driver will unload some LPG into cylinders before reaching the customer.

3. Kerosene, Water?

The tank driver unloaded some LPG and replaced it with kerosene or even water so that the user felt that the weight of the unloaded goods was accurate. Therefore, the user does not know that not all of the unloaded LPG is propane/butane, and this kind of deficiency has really happened. If the user uses molecular sieves to purify the propellant gas, it will lead to very bad results.

4. Empty Hoses, Empty Conveyor Pipes

For safety reasons, some LPG companies insist that tankers be drained of their hoses before they depart, and aerosol plants also drain the lines used to fill tanks.

During storage, pumping and transfer to the filling machine.

5. Blow, Blow, Blow Again

Poor quality propellant gas equipment can cause the gas to vaporize in the pipeline and some of the liquid phase gas to convert to the vapor phase, which makes it impossible to fill the correct weight.

To do this, the vaporized propellant gas must be blown out of the pipe until only liquid phase propellant is present in the pipe.

Good equipment will not experience this condition, indeed bad equipment will need to be blown out several times a day to maintain the correct weight.More pumping problems occur on hot days than cold days, and conditions are worse during the day than at night.

6. Recirculation and Less Inflation

Inferior propellant gas with pneumatic pumps are completely incapable of recirculation, those with typical centrifugal pumps determine pressure at the tank and recirculate immediately after the pump into the tank.

The only way to maintain the purity of the liquid propellant gas while the liquid piping is empty and filled is to purge all of the vapours from the propellant gas.

A good equipment transports the propellant to a machine, from which it is returned to the tank for recirculation. The vapour in the pipeline returns to the storage tank and rarely or never needs to be purged.

7. General Leakage

A small leak is normal in all facilities, tank joints, pump joints or service lines. The use of a sensitive “leak detector” enables the maintenance engineer to locate and stop the leak.

If your company purchases clean, odorless propellant gas, you do not need to read points 8, 9, 10, 11 and 12 below. Only a company that deodorizes its own propellant gas is likely to have leaks in these areas.

8. Inappropriate Deodorization Programs

Users deodorize LPG before using it, and if the molecular sieves used for deodorization are changed prematurely, there will be a loss of propellant gas. An empty deodorizing column will always result in some loss of propellant.

9. Inferior Propellant Gas

In some places, inexpensive propellant gases always have an unpleasant odour, and the use of such gas requires frequent changes of molecular sieve particles, which means more propellant gas is lost.

10. Improper Purification Process

Some companies use incorrectly graded molecular sieve particles, while others try to use silicone or aluminum glue or activated carbon particles.

All of these methods may require more frequent material changes than using the correct type of molecular sieve, and more frequent material changes mean more loss of propellant gas.

11. Wet Molecular Sieves

The deodorization capacity of the wet sieves is reduced and the working time of the sieves is shorter than that of the dry sieves, and early replacement of the sieves results in a loss of propellant gas.

For this reason, never open a bucket with a new dry molecular sieve when it is raining and remember to reseal the bucket tightly as soon as possible after opening it.

12. Inferior Molecular Sieves

Qualified molecular sieves are capable of absorbing 20%~30% by weight of contaminants, while some very inexpensive molecular sieves can only absorb 10%~15% by weight of contaminants. This means that the sieves have less time to be used, and changing the sieves earlier results in a loss of the propellant gas.

During the aerosol filling process.

13. Poor Quality Aerosol Filling Equipment – Frequent Leak Detecting

Good quality filling equipment does not leak even after many years of use, whereas inferior filling equipment must be checked regularly with a “leak detector”.

14. Poor Quality Aerosol Filling Equipment – Cans Positioning Failure

When filling propellants, quality equipment positions the cans properly in the center with little damage loss of valve. Inferior machines often fail to position the cans properly, resulting in increased leakage, valve damage and loss of propellant gas.

15. Outdated Aerosol Filling Equipment

Old, aging machines fail to properly position the cans when filling the propellant gas, causing some cans to be damaged, resulting in unnecessary loss of propellant gas.

16. Poor Quality Aerosol Filling Equipment – Imprecision Filling

Poor-quality aerosol filling equipment is often imprecision filled, with some cans underfilled and some overfilled, which means that too much propellant gas is used unnecessarily.

17. General Leakage

If there is a leak in the filling machine, a sensitive “leak detector” enables the service engineer to locate and stop the leak.

18. Gas Filling Seals Are Critical

Quality equipment has a positive pressure mechanical seal that stops the propellant gas flow when the can is filled. There is a slight popping sound as the filler head leaves the can, but no vapor cloud of propellant gas is visible. Also, the fill head never ices.

19. Cheap Equipment May Not Have Spare Parts

Some companies buy spare parts locally or manufacture their own, and it is difficult to know the quality of these spare parts, which can lead to large leaks. There are even companies that tell their operators “we don’t have any spare parts, just leave the machine running by whatever means”. Serious accidents follow.

20. Fill Gas with Nozzle

We know that any material between the inflation seal and the aerosol valve seal will leak. When inflating with a nozzle, there is more space between the inflation head seal and the aerosol valve seal, so there will be more leaks.

21. Ruptured Hoses or Couplings

This is a serious issue that can easily lead to accidents, and one of the biggest differences between a quality machine and an inferior one is the quality of the seals and hoses.

22. Poor Quality Cans and Valves

They leak more than good quality components and when a can or valve leaks, the propellant is lost (along with the can, valve and fluid).

23. Bad Valve Sealing

A poor seal results in the loss of cans, valves, fluids, and propellant.Good companies that seal properly have a scrap rate of less than 0.05% of their production, but in reality many companies have scrap rates of 0.5%, some as high as 1.0%.

The following table shows the loss of propellant gas in each case, based on a 100g propellant gas filled in a can.

| Loss Ratio(%) | Can Loss Per 1 Million Cans | Propellant Loss Per 1 Million Cans(KG) |

| 0.05 | 500 | 50 |

| 0.50 | 5,000 | 500 |

| 1.00 | 10,000 | 1000 |

These numbers may not seem like much, but when you add in all the other losses in the bad section, it becomes a large amount. At the same time this poses a serious safety risk if the material is filled with highly flammable fluids such as kerosene-based insecticides, ethanol-based sprays or Methyl benzene, xylene.

Sum Up

All aerosol filling plants lose propellant gas, but some lose very little, while others lose a lot. Above we have listed 23 steps in which aerosol filling plants may lose propellant gas, but there are certainly others that are not listed.

To be sure, no company loses propellant gas in all of the above 23 steps. However, all companies lose propellant gas at several different points in the process, and the total loss is the sum of the losses at each bad point.

Virtually all companies can reduce their propellant losses. When propane/butane was very cheap, this loss was not a problem. But today, they are very important. So, using quality equipment and building a quality propellant facility will result in significant savings in propellant costs.

Recent Posts

-

2 Ways You Can Take to Avoid Aerosol Can Corrosion Leaks

After many years of scientific research, it has been found that HFCs, which used to be used as aerosol propellants, have a certain destructive effect on the ozone layer, so the production of CFCs in Europe and the United States is restricted by law.

After many years of scientific research, it has been found that HFCs, which used to be used as aerosol propellants, have a certain destructive effect on the ozone layer, so the production of CFCs in Europe and the United States is restricted by law. -

9 Key Factors to Consider will Make You Select the Right Aerosol Valves

Aerosols have played an important role in people's daily lives since their invention, production and application in the 1920s. It has a wide range of applications, such as personal care, household care, pest control, medical solutions, industrial care and food, etc., bringing great convenience to human life.

Aerosols have played an important role in people's daily lives since their invention, production and application in the 1920s. It has a wide range of applications, such as personal care, household care, pest control, medical solutions, industrial care and food, etc., bringing great convenience to human life. -

8 Advantages to Use Nitrogen(N2) as Aerosol Propellant Gas

70 years after the birth of the aerosol industry, a new propellant was discovered - nitrogen and pure compressed air containing 78% nitrogen. These gases have been known for centuries. But until then, they had not been seriously considered because of two major drawbacks: the majority of the gas escapes when sprayed obliquely or

70 years after the birth of the aerosol industry, a new propellant was discovered - nitrogen and pure compressed air containing 78% nitrogen. These gases have been known for centuries. But until then, they had not been seriously considered because of two major drawbacks: the majority of the gas escapes when sprayed obliquely or

Maximize Your ROI

by Investing in Our Cost-Effective Aerosol Filling Machines.

Contact Us

Copyright© 2019 Dawsom Mechanical & Electrical Co., Ltd. All Rights Reserved.