Bag On Valve Aerosol Technology 101 [Part One]

10/09/2019The market has witnessed a rapid growth of Bag on valve(BOV) technology these years, especially in the field of pharmaceutics, personal care, and household care.

Bag on valve technology shows its outstanding advantages in many aspects. It is able to isolate the product from the propellant gas, thus prolonging the shelf life dramatically. It uses non-flammable gas(Nitrogen or compressed air) as the propellant gas, which is much safer than the traditional aerosol technology.

According to the report of a related market research institute, the CAGR(compound annual rate of growth) of the bag on valve technology is estimated at 4.4% between 2017 and 2024. And obviously it has a promising future because of its higher recycle rate.

1. The Story Of Bag On Valve Technology

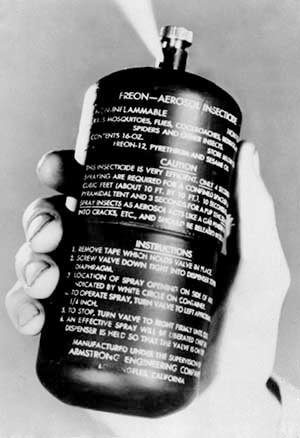

“The first aerosol spray can patent was granted in Oslo in 1927 to Erik Rotheim, a Norwegian chemical engineer. “

After Erik Rotheim, there are also other people doing the research on the aerosol spray can. American Julian S. Kahn received a patent for a disposable spray can, but it was not developed fully.

The modern good use of the aerosol spray can started from Americans Lyle Goodhue and William Sullivan. Their invention is regarded as the ancestor of many commercial aerosol spray products.

In 1982, the first BOV design patent was filed in Europe. A flexible and multi-layer pouch is welded onto the valve. The gas is filled into the bag and outside the pouch where the formula is contained.

2. What Is Bag On Valve?

There are many formula delivery methods, and aerosol spraying is one of them.

You want an aerosol spray, then you need at least 3 basic components: a container, formula(usually liquid or semi-liquid, and pressure).

This applies to the classic traditional aerosol system. The pressure comes from the propellant gas(like LPG and DME). These propellant gases are liquefied, and there is pressure once they vaporize.

When it comes to the bag on valve technology, it also applies. The difference is the formula location and the propellant gas.

So, bag on valve is a system, which includes some components. And the bag on valve can only work when all components are there.

Usually, it includes the below components.

- Container

- Bag on valve

- Propellant gas

Apart from the common bag on valve aerosol of aluminum can and tinplate can, there are some other types of BOV packages in some rare applications.

This is a transparent bag on valve in plastic can released by APPE. This SprayPET is an alternative to standard aluminum bag on valve cans.

This is dual dispensing bag on valve package is released by Toyo. It can spray two compounds out and mix before sprayed out.

This is similar to the regular bag on valve. The difference is the size is 20mm diameter, and it is mainly used in small dosing applications.

3. How Does Bag On Valve Aerosol System Work?

You may say, “well, it’s simple, just press the actuator, then the formula is sprayed out.”

There is no problem with it. But how is the formula sprayed out?

If we ask ourselves a question after another question, we can make it further clear.

The propellant gas(usually Nitrogen or compressed air) is filled inside the can with pressure about 0.3~0.4Mpa. And the pressure inside the can turns to about 0.6~0.7Mpa after the formula liquid is filled.

The pressure squeezes the bag. Once you press the actuator, the channel is open and the formula passes the valve stem channel, and also the actuator channel which can form the fine mist spray.

The spraying will continue as long as you press the actuator until the formula liquid runs out.

It should be noticed that the pressure is from every angle to push the bag. That means you can hold the can at any angle to let the spray out.

Once your fingers leave the actuator, the channel is closed, and the spray stops.

From the picture above, we can see that the propellant gas is sealed inside the can and never come out together with the liquid formula, which is a very distinctive difference compared to the regular aerosol package.

The gas stays inside the can even the bag is empty. And there is still pressure inside the can. This is also why usually the product can be sprayed completely.

4. What Are The Benefits of Using Bag On Valve?

Compared to the traditional aerosol package, bag on valve system is beneficial to aerosol manufacturers, the consumers and also the environment.

Here below are some outstanding advantages of the bag on valve system.

1) The product can be 100% emptying.

Different from the traditional aerosol package, the bag on valve package system permanently insulates the product from the propellant gas by the bag inside the aerosol can.

The bag is flexible so that the propellant gas(compressed air or Nitrogen) can squeeze the bag until almost 100% of the product is dispensed.

In traditional aerosol packages, the propellant gas is possibly used up before the product runs out.

2) Non-flammable.

The traditional aerosol system uses flammable propellant gases like LPG and DME, while bag on valve package system uses compressed air or Nitrogen as the propellant gas. Bag on valve package system is safer.

3) More hygiene and environment-friendly

The gas and product in bag on valve package are isolated. The product is contained in the bag, and the propellant gas is contained in the can but outside the bag. The product is sprayed by means of squeezing of the bag, which can avoid contamination. Besides, the bag on valve package will not generate VOCs.

4) No need for shaking

Some products like spray paint are packaged in the traditional aerosol system. Usually, they need to be shaken well before using to ensure the spray is even. While in bag on valve package, there is no need for the shaking.

5) Longer shelf-life

For some oxygen-sensitive products, bag on valve package can prolong the shelf life because there is almost no oxygen in the bag.

6) More widely application

Because bag on valve package can isolate the product and the propellant gas, so it can be applied in more applications like shaving foam, oil, gel, ect. Bag on valve package can also be used for the high viscous product.

Helpful Tips: How to tell if it’s bag on valve package or regular traditional package?

It’s simple. Hold the can and shake it. For regular traditional package, there is the sound of like shaking the can container water inside. If there is no such sound, then it is bag on valve package.

In Bag On Valve Aerosol Technology 101 [Part Two], we’ll discuss more on the bag on valve knowledge. Hope it’s helpful to you.

Recent Posts

-

2 Ways You Can Take to Avoid Aerosol Can Corrosion Leaks

After many years of scientific research, it has been found that HFCs, which used to be used as aerosol propellants, have a certain destructive effect on the ozone layer, so the production of CFCs in Europe and the United States is restricted by law.

After many years of scientific research, it has been found that HFCs, which used to be used as aerosol propellants, have a certain destructive effect on the ozone layer, so the production of CFCs in Europe and the United States is restricted by law. -

23 Aerosol Propellant Losses Will Cost You Money and Ruin Your Plant

Did you know that aerosol propellants can be lost in 23 places? It is not only the propellant gas and money that are lost, but also the possibility of destroying the plant. Since there is almost no way to monitor and measure the use of propellants, it is very easy to lose them

Did you know that aerosol propellants can be lost in 23 places? It is not only the propellant gas and money that are lost, but also the possibility of destroying the plant. Since there is almost no way to monitor and measure the use of propellants, it is very easy to lose them -

9 Key Factors to Consider will Make You Select the Right Aerosol Valves

Aerosols have played an important role in people's daily lives since their invention, production and application in the 1920s. It has a wide range of applications, such as personal care, household care, pest control, medical solutions, industrial care and food, etc., bringing great convenience to human life.

Aerosols have played an important role in people's daily lives since their invention, production and application in the 1920s. It has a wide range of applications, such as personal care, household care, pest control, medical solutions, industrial care and food, etc., bringing great convenience to human life.

Maximize Your ROI

by Investing in Our Cost-Effective Aerosol Filling Machines.

Contact Us

Copyright© 2019 Dawsom Mechanical & Electrical Co., Ltd. All Rights Reserved.