Why Is There Residue in An Aerosol Can?

31/07/2019In your daily life, you may have faced the phenomenon that the aerosol hair spraying became smaller and smaller until stopped completely. However, you found that there was much content inside while shaking it in hand.

What is going on there?

Before figuring it out, let’s come to make clear how the spraying takes place first.

Put in a professional term, hair spray is a type of aerosol product. It is known that aerosol is a sealed container with pressure inside. And the pressure must be higher than the atmospheric pressure to form pressure difference. Otherwise, there would be no power to activate the spraying move.

Spraying failure may come from various possibilities. It may be the product functional problems, like leakage. Or, it might also be a blockage. The channel is opened to squeeze contents out once the actuator is pressed. The spraying can’t take place if the channel is blocked.

There is one more possible cause. Due to improper usage, the propellant gas is released “in advance” by the end-user, and only liquid content is left in the can. In such condition, surely there can’t be any spraying. It’s like the automobile can’t be ignited after gasoline runs out.

But how come the gas is released “in advance”?

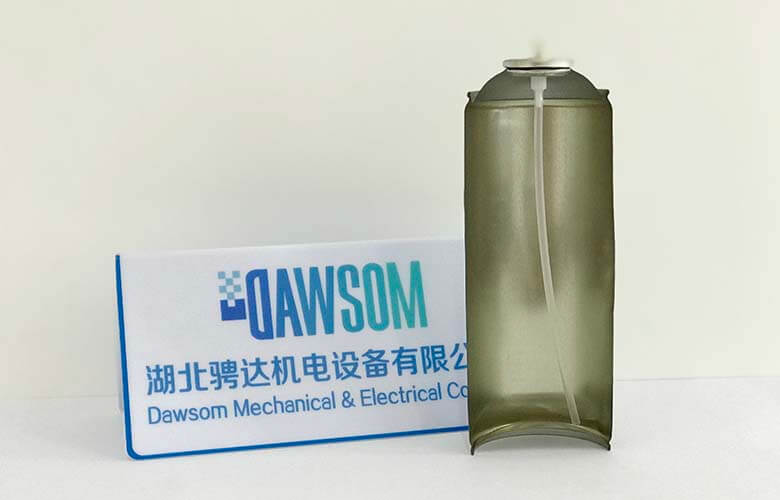

Let’s take a look at the aerosol intersecting pictures first.

The 360° valve can spray out the contents at any angle, no matter upside or downside. However, the regular valve can spray out the contents only at upside angle.

The spraying failure takes place under below occasions.

1. Hold the aerosol can upside down.

The propellant gas stays above the liquid content once the bottle is placed upside down. The gas will be sprayed out through the valve dip tube, while the liquid can’t and is left inside the can. Once the gas is sprayed completely, there would be nothing else as you keep pressing the actuator.

Solution: hold the can upside while spraying.

2. No matter it goes with 360° valve or regular valve, even though the bottle is not held upside down, the gas will also be sprayed out first as long as the angle is not proper.

In the above picture occasions, the valve dip tube end raises up above the liquid surface, while the liquid surface is below the valve. Once the channel is open at this time, the gas will also be sprayed out, while the liquid content remains inside the bottle.

Solution: Change to another angle workable, or spin the actuator to let the dip tube under the liquid surface.

3. The tip tube end is just a little above the liquid surface even the angle is proper.

The can is held upside, and the tip tube end does not touch the liquid because the liquid volume is not enough.

Solution: spin the actuator by 180°.

Now, what else spraying failures did you encounter? Welcome to email us for further discussing at info@dawsom.com.

Recent Posts

-

2 Ways You Can Take to Avoid Aerosol Can Corrosion Leaks

After many years of scientific research, it has been found that HFCs, which used to be used as aerosol propellants, have a certain destructive effect on the ozone layer, so the production of CFCs in Europe and the United States is restricted by law.

After many years of scientific research, it has been found that HFCs, which used to be used as aerosol propellants, have a certain destructive effect on the ozone layer, so the production of CFCs in Europe and the United States is restricted by law. -

23 Aerosol Propellant Losses Will Cost You Money and Ruin Your Plant

Did you know that aerosol propellants can be lost in 23 places? It is not only the propellant gas and money that are lost, but also the possibility of destroying the plant. Since there is almost no way to monitor and measure the use of propellants, it is very easy to lose them

Did you know that aerosol propellants can be lost in 23 places? It is not only the propellant gas and money that are lost, but also the possibility of destroying the plant. Since there is almost no way to monitor and measure the use of propellants, it is very easy to lose them -

9 Key Factors to Consider will Make You Select the Right Aerosol Valves

Aerosols have played an important role in people's daily lives since their invention, production and application in the 1920s. It has a wide range of applications, such as personal care, household care, pest control, medical solutions, industrial care and food, etc., bringing great convenience to human life.

Aerosols have played an important role in people's daily lives since their invention, production and application in the 1920s. It has a wide range of applications, such as personal care, household care, pest control, medical solutions, industrial care and food, etc., bringing great convenience to human life.

Maximize Your ROI

by Investing in Our Cost-Effective Aerosol Filling Machines.

Contact Us

Copyright© 2019 Dawsom Mechanical & Electrical Co., Ltd. All Rights Reserved.